Product innovation

Life Fitness product innovation begins with product design and conception and doesn’t end until our fitness equipment ships out of the warehouse. It’s essential to creating the best fitness equipment in the industry.

STATE-OF-THE-ART TOOLS

The Cintiq pen display lets the creative minds at Life Fitness bring the most innovative new products to life.

3D PRINTER

The 3D printer lets us create moulds of specific parts in-house, quickly and without the need for expensive machining.

FOAM MODELS

Life-size foam models allow the design team to inspect every detail of each new product. This saves time, money and ensures that each product is fit for every exerciser before it ever shows up on the production line.

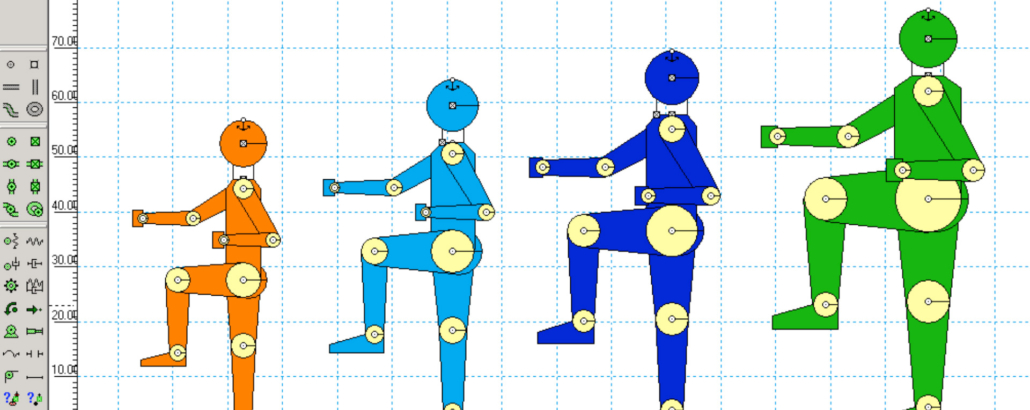

KINEMATIC TESTING

Kinematics testing determines the way the body moves. Input from this testing has been essential when designing cardio equipment like cross-trainers that have an elliptical path that mimics natural running.

PRESSURE TESTING

Pressure analysis on the soles of the feet and the seat of Lifecycle bikes determines hot spots and ultimately enhances user comfort.

VO2 TESTING

VO2 testing measures how much oxygen exercisers metabolise, which can be converted into calorie burn. Extensive data across a wide variety of exercisers results in “calories burned” displays on Life Fitness equipment that are extremely accurate.

ELECTROMYOGRAMS

Electromyograms measure the electrical activity in muscles and provide valuable insight into muscle engagement during exercise.

ROBOT TEST

Simulates seven years of wear and tear on equipment in just seven months.

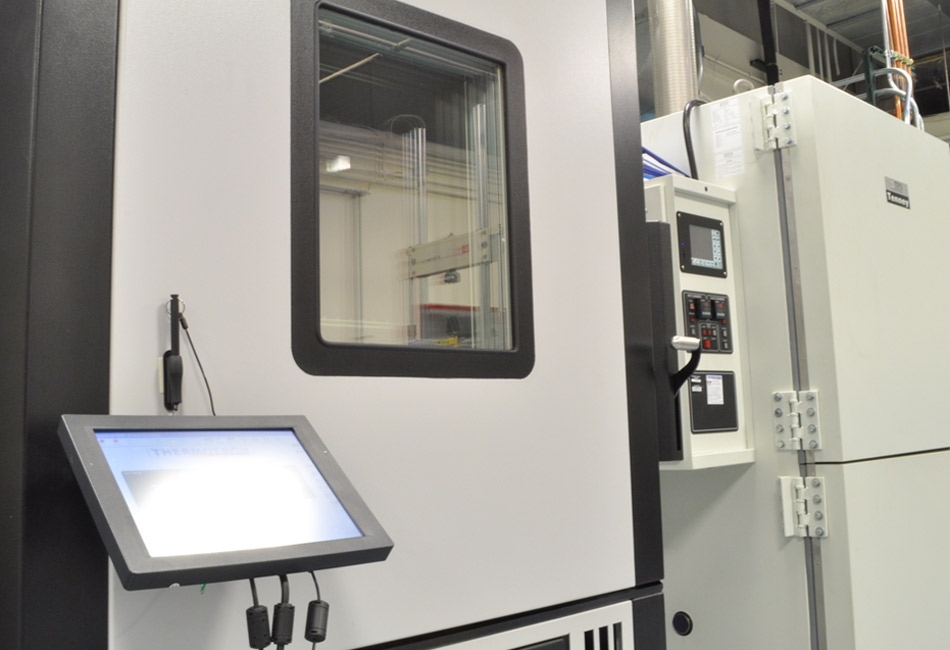

THERMAL SHOCK

Tests equipment over a 200-degree temperature range to ensure it’s suitable for a wide range of environments.

SHAKE TEST

Places intense vibrations on the equipment to test its ability to stand up to repeated use by exercisers

ANECHOIC CHAMBER

Tests emissions of electromagnetic fields to ensure that Life Fitness equipment doesn’t interfere with other systems or devices in your gym.

MAXIMUM LOAD TEST

Pushes a machine to its absolute limits, and conditions well above what equipment ever faces in a facility.

3% of our products are randomly selected from the production line, assembled and tested before being shipped. The experienced testers at Life Fitness can detect even the slightest equipment flaw.

For more than 20 years, Charles Long Jr. has been making sure Life Fitness treadmills live up to rigorous standards. He and three other inspectors try out treadmills, while each is still on the production line, to ensure that they’re ready to ship. Charles walks on 50 new treadmills each day and puts in more than 250 miles in a year.

Building the best fitness equipment in the industry is the goal from the time Life Fitness conceptualises a product to when it ships to a customer.

THE FOUNDATION OF LIFE FITNESS IS BASED ON TECHNOLOGY

In 1968, Life Fitness created the Lifecycle exercise bike. It employed groundbreaking technology and was the first piece of electronic exercise equipment ever created. Over the next four decades, we’ve taken the steps needed to stay ahead of technology

APP PARTNERSHIP

Life Fitness equipment interacts with popular fitness apps to provide exercisers with the connection they expect.

WEARABLE INTEGRATION

Multiple wearable tracking devices provide immediate and accurate results after workouts on select Life Fitness cardio equipment.

EFFORTLESS CONNECTION

Bluetooth compatibility connects exercisers to equipment for workout tracking, hands-free heart rate monitoring, and enhanced entertainment.